ARTICLES

Follow Us

Be the first to know

From Burn Rate to Breakthrough: Why Aerospace Companies Fail, and How to Fix It Before It is Too Late

By:

Arman M Nazari

President,

Global Technical Resources | Aerospace & Defense SME

1: The Mirage of Momentum

In aerospace, failure does not always announce itself with an explosion. More often, it begins quietly, with silence from a partner, a missed update from the engineering team, a financial report that does not quite add up. It begins when the founders stop talking to each other except in rehearsed stakeholder calls. It begins when engineering swells with headcount, but the product is no closer to flight. It begins when a once, excited investor starts quietly ghosting quarterly updates.

Most people outside the industry assume that aerospace failures are technical in nature, that it must have been a bad design, an unexpected physics problem, or a dramatic regulatory barrier that sank the ship. But those of us inside the industry know better. Aerospace ventures die from things far more mundane: bad communication, poor planning, and a fundamental misunderstanding of what it actually takes to bring a vehicle or system from napkin sketch to certified reality.

Time and again, I have watched programs that should have flown, literally and figuratively, collapsed under the weight of their own complexity, egos, or inertia. And often, it was not because the idea was bad. It was because no one ever took the time to ask the most painful, necessary question:

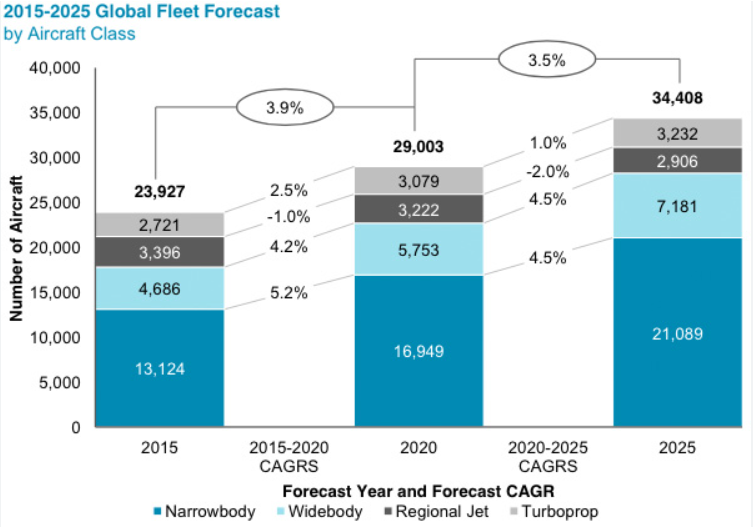

How many units do we need to sell to break even, and how do we get there?

2: The Quiet Descent

Let me speak to the executive who is reading this with a pit in their stomach, you know things are not working. You can feel it. The engineering team is always “a few weeks away” from delivery, but somehow never gets there. You have already burned through two rounds of investor capital and are preparing a pitch deck to raise a third, hoping no one asks too many hard questions about unit economics. The prototype looks impressive, but the weight margins are tighter than ever, and certification feels like an abstract dream rather than a plan of record.

Or maybe you are the investor. You sat on that Zoom pitch a year ago, heard words like “disruption,” “dual, use,” “low, SWaP,” and nodded as the founders threw around comparisons to SpaceX, Anduril, or Skydio. The slides were slick. The model looked aggressive. You signed the check.

And now?

Now you are looking at line items that don’t make sense, deliverables that are perpetually late, and an executive team that is long on vision but short on execution. You are starting to wonder: Did I just fund a science fair project? Or worse, am I about to be the last one holding the bag?

You are not alone.

What you are experiencing is not unique. It is happening, right now, across dozens of aerospace startups and even legacy players attempting to pivot into next, gen platforms. The market is flooded with half, baked UAVs, dead, on arrival VTOLs, propulsion systems that cannot pass a test stand, and “platform plays” that never got off the whiteboard. And in many cases, these failures are not due to bad science or lack of funding, they are due to a complete lack of operational engineering discipline and business clarity.

3: The Illusion of Progress

One of the most dangerous things in aerospace is the illusion of progress. Teams stay busy. Whiteboards get filled. Test articles are machined. Meetings are held. Money is spent.

But is the program actually moving forward?

If you cannot quantify what success looks like, in terms of breakeven analysis, margin per unit, certification risk, or operational readiness, then you are not moving forward. You are just burning the runway.

Far too many aerospace companies confuse activity with advancement. They hire talent, accumulate parts, lease office space, and produce impressive prototypes. But ask the hard financial questions, and you get vagueness or deflection:

- “We’re still refining the cost model.”

- “We need to finish integration before finalizing margins.”

- “Once we get through flight test, we’ll model breakeven.”

This is delusional thinking. If you do not understand the business case before you build, you are gambling, not executing.

In aerospace, every gram counts, every dollar matters, and every decision compounds. If your company cannot tell you how many units you need to sell to become profitable, and at what cost, you are flying blind into a storm.

And investors? They may not say it directly, but they know. They feel it in the way your monthly updates start to sound repetitive. They see it in the way engineering burns are rising but the milestones are not. They can tell that your once, promising venture is no longer looking like a 10X return, but an expensive lesson.

4: The Real Cost of Failure

Failure in aerospace is not just about money. It is about the human capital, the engineers who give their best years to a platform that never lifts off. It is about the suppliers who extend the terms because they believe in the mission, only to watch it implode. It is about the founders who get blamed for bad planning when they are never given the tools or experience to succeed.

It is about the opportunity cost of what could have been built, if only someone had stepped in earlier and said:

“This is not working. Let us fix it.”

Worse, failure ripples through the industry. Every failed drone startup makes the next one harder to fund. Every failed air taxi program undermines public and regulatory trust. Every failed propulsion spinout makes it harder for real breakthroughs to find oxygen.

It does not have to be this way.

5: Why Aerospace Teams Lose Clarity

Clarity should be the foundation of any aerospace venture, clarity of purpose, clarity of product, clarity of path. But as the program matures, that clarity often dissolves under pressure. You begin with a sleek, minimal vision: a UAV platform that solves a specific tactical gap, a novel hybrid propulsion unit, a better cargo drone. But then… scope creep begins.

Suddenly, you are building a UAV that is also a VTOL that can carry 200 lbs. and fly for 3 hours and integrate autonomous swarm tech and be ruggedized for extreme weather. Every stakeholder adds a feature. Every meeting adds complexity. Before you know it, your Minimum Viable Product has become a Maximum Theoretical Complication.

And no one wants to be the one to say stop.

Meanwhile, engineering leaders are caught in the middle, trying to hit moving targets while maintaining quality and safety. Teams are spread thin, burning hours chasing performance that might not even be required. Marketing is overpromising timelines. Executives are planning next year's funding round but cannot articulate what the current round was supposed to deliver.

This is how clarity dies: not in a fireball, but through dilution.

Eventually, your startup begins to feel like a government program: heavy, slow, political, and ultimately, disconnected from the user. Except there is one big difference: the government still pays you. Your investors do not.

6: What Breakeven Really Means in Aerospace

In any business, breakeven analysis is a fundamental exercise. But in aerospace, it is everything.

Why? Because this industry has some of the highest capital intensity, longest development cycles, and strictest regulatory burdens of any field on Earth. If you are not constantly measuring against your breakeven point, and refining your path to reach it, you are building a rocket with no launchpad.

And yet, when we ask many aerospace startups or product teams: How many units do you need to sell before you breakeven? They do not know.

They give vague answers: “It depends.” “Once we scale.” “After certification.” These are not answers. These are deflections.

The reality is that breakeven is not a static number. It evolves. It should be reforecast every time a design changes, every time your supply chain shifts, every time a delay occurs.

You need to understand:

- Fixed costs: Engineering, tooling, certification, insurance, overhead

- Variable costs: Materials, labor, testing, logistics

- Unit price sensitivity: What will your customers actually pay, not what you hope they will.

- Volume forecasts: What contracts are real vs. speculative.

- Cash runway: How many months of burn you can sustain before the next tranche.

And here is the truth no one wants to admit: Sometimes, the breakeven point becomes unreachable. And when that happens, you need to pivot, or exit, quickly. Not two years later after wasting more money. Quickly.

This is where most companies fail. They do not run the numbers, or they ignore them when they do. They hope for a strategic partner, a defense contract, or a miracle investor. But hope is not a strategy. Math is.

7: The Path to Rescue, GTR’s Turnaround Playbook

At Global Technical Resources, we have made a career out of turning around programs that everyone else had given up on.

We do not show up with slide decks. We show up with checklists, calculators, and CAD models. We roll up our sleeves and start asking hard questions:

- Why hasn’t this program shipped?

- What are the real structural bottlenecks?

- Where are the margins disappearing?

- Who is making decisions, and based on what data?

We break the problem down across five critical dimensions:

- Program Viability – We assess whether your current platform, as scoped, has any realistic path to technical success and commercial viability. If it does not, we tell you, directly.

- Engineering Discipline – We audit your design, analysis, testing, and review processes. We identify what is broken in your workflows and what needs to be restructured.

- Business Model Alignment – We realign your cost model and market assumptions with actual breakeven paths, not wishful thinking.

- Team & Roles – We identify gaps in your leadership structure and recommend realignments. Sometimes the wrong CTO is more dangerous than no CTO.

- Customer Focus – We help revalidate your value proposition with real customers, not just pitch decks.

We have done this across UAV platforms, defense tech spinouts, VTOL systems, propulsion startups, and even international programs under contract pressure. We do not just advise, we execute. We help you rescaffold the business, identify what is salvageable, and launch a new trajectory.

8: What Can We Do?

Some of the companies we have worked with are now profitable. Some were sold. A few had to shut down, but they did so gracefully, preserving IP and investor trust. That too is a win, in a world where many startups burn capital and reputation to the ground.

We can help drone companies stuck in regulatory limbo find viable defense use cases. We can help propulsion startups repackage their tech into simpler, more licensable modules. We can save airframe companies millions by catching structural flaws in their FEM before manufacturing.

We have also built our own platform ideas. From autonomous aerial munitions to hybrid, electric personal aircraft, we know what it means to get a program flight, ready, not just technically, but financially and operationally. We understand both the engineering pain and the business pressure that executives face. That is why we have become a trusted partner not just to engineers, but to boards and investors alike.

9: Join the Comeback – GTR’s Call to Struggling Ventures

If you are reading this because your program is in trouble, I have one message: It is not too late. But you must move fast.

There is no shame in seeking help. In fact, the best founders and executives do it early, before they burn through the rest of the budget. Before they lose their team. Before their brand becomes synonymous with “almost.”

GTR exists for these moments.

Whether you want to:

- Rescue a failing program.

- Recast your business model.

- Spin out a new concept.

- Evaluate a technical roadmap.

- Secure defense dual, use pathways.

- Or simply get a second opinion

We can help. We are not here to judge. We are here to build. To fix. To guide. To restore.

You have already invested too much, time, money, trust, to let this end in silence.

Let us help you turn the story around.

10: Building the Future Together, GTR as Your Partner, Not Just Your Consultant

Rescuing programs is only part of what we do. At GTR, we do not just fix broken ventures, we create new ones.

We constantly develop next, generation aerospace platforms across defense, commercial aviation, and emerging technologies. From autonomous drones and advanced UAV swarms, to hybrid, electric personal aircraft, modular propulsion systems, next, gen helicopters, and defense weapon platforms, we live at the forefront of aerospace innovation.

And we believe in shared risk, shared reward.

For the right partners, GTR can go beyond consulting. We can become co-founders, equity partners, or joint venture collaborators. If your company has manufacturing capabilities, engineering resources, or capital to deploy, we can align you with new programs that are already in advanced stages of concept and design.

Imagine this:

- A defense contractor struggling with underutilized facilities pivoting into UAV production through a joint venture.

- An aerospace supplier entering the high, margin propulsion market by co-developing disruptive electric motor technology.

- A midsize firm lacking R&D capacity gaining access to GTR’s pipeline of proprietary designs, from weapon systems to advanced commercial platforms.

These are not hypothetical. These are opportunities we can bring to life today, in partnership with teams that have the drive and assets to execute.

We see every struggling aerospace company as more than a cautionary tale, we see them as sleeping giants, waiting to be redirected toward projects that succeed.

When you work with GTR, you do not just get a lifeline for your current program. You gain access to a portfolio of future, ready projects that can match your capabilities, facilities, and ambitions.

We are open to partnerships based on equity sharing, joint ventures, or capital participation. We can help you rebuild not just your company’s reputation, but its future pipeline.

The Future Is Still Yours to Build

If your current program is failing, let us fix it. If you need a new one, let us create it.

At GTR, we do not just consult, we innovate, we partner, we build.

The aerospace industry rewards those who adapt, who refuse to quit, and who know when to ask for help. If you have read this far, you already know what needs to be done.

The only question left is: Are you ready to act?