ARTICLES

Follow Us

Be the first to know

What Executives Get Wrong About Aerospace Engineering and How to Fix It?

By:

Arman M Nazari

President,

Global Technical Resources | Aerospace & Defense SME

After nearly years in aerospace engineering , from structural analysis, test labs to certification war rooms , I've seen firsthand how technical misalignments between engineering and executive leadership can derail programs, budgets, and even careers. This isn’t a matter of intelligence or intent. It's a matter of perspective and bridging that gap, can be the difference between project failure and a billion-dollar breakthrough.

Here are five key misconceptions executives often have about aerospace engineering, and what they should do instead:

1. Engineering Isn’t Linear, and Progress Isn’t Always Visible

The Misconception:

“If we're not seeing hardware progress, the team must be stuck.”

The Reality:

Much of the aerospace engineering happens invisibly , in simulations, modeling, documentation, and cross-functional reviews. Critical work like FEM stress convergence, material trade studies, and verification matrices can take months before a single bracket is fabricated.

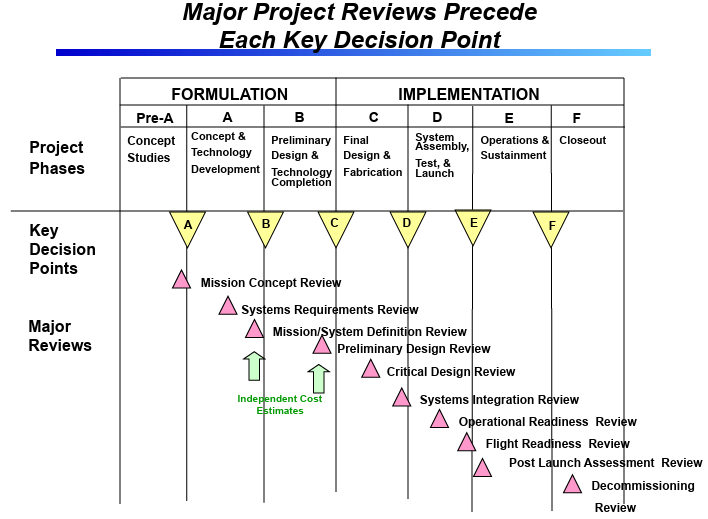

Aerospace development also unfolds through clearly defined technical gates, most notably PDR (Preliminary Design Review) and CDR (Critical Design Review). These are not ceremonial, they represent rigorous checkpoints for structural integrity, system integration, and compliance planning.

The Fix:

Executives need to ask better questions: “What are the current technical bottlenecks, and how are they being validated?” Tracking engineering through digital milestones, not just physical parts create a more accurate program picture.

2. Certification Is Not a Checkbox — It’s a Design Driver

The Misconception:

“Let’s design the best product and worry about FAA later.”

The Reality:

In regulated aerospace, certification isn’t something you “get” at the end, it shapes every decision from day one. Whether you’re building under FAR Part 23 (small fixed wing), Part 25 (transport category), Part 27 (light rotorcraft), or Part 29 (transport helicopters), compliance defines the limits of innovation. Ignore it, and you’ll redesign your product three times over at triple the cost.

The Fix

Integrate certification engineers early. Executives must view DERs, compliance matrices, and DO-178C/DO-254/ARP4754A processes not as paperwork, but as strategic tools to de-risk market entry.

3. Cost-Cutting Engineering Time Often Costs More Later

The Misconception:

“We can compress the design cycle by reducing analysis time.”

The Reality:

Cutting corners in early-stage design validation creates failure modes that show up during flight tests, delaying programs by months. For every dollar saved in Phase I, you may spend ten on Phase IV.

This is especially true in stress engineering, where thorough analysis of load paths, fatigue life, and margin-of-safety calculations determines whether your design is even certifiable. Structure touches everything , avionics mounting, wiring runs, pressurization bulkheads, landing gear loads, so ignoring stress engineering risks the entire system architecture.

The Fix:

Executives must understand that robust trade studies, stress loops, and test readiness reviews are investments in long-term speed and quality, not bureaucratic delays.

4. Engineering Talent Is Not Easily Interchangeable

The Misconception:

“We’ll just hire more engineers if things slip.”

The Reality:

Aerospace isn’t plug-and-play. Domain knowledge in legacy programs, niche software, or compliance history can’t be replaced with headcount alone. A seasoned loads engineer or systems integrator is often worth more than five generalists. In stress and structures especially, institutional knowledge, like knowing which bracket has failed three times before, is irreplaceable.

The Fix:

Executives should prioritize retaining core knowledge carriers and avoid burnout cycles. Respecting technical continuity is key to program health.

5. Innovation Doesn't Mean Reinventing the Wheel

The Misconception:

“We want a moonshot, let’s go 100% new.”

The Reality:

Revolutionary designs sound great in boardrooms but often fail in test bays. The best-performing programs balance innovation with proven architectures. There’s a reason why NASA, Boeing, and SpaceX iterate off heritage platforms.

The Fix:

Encourage innovation in modularity, materials, or manufacturing, but anchor it in flight-proven systems. That’s how real engineering innovation is scaled.

Final Thought

If aerospace engineering feels slow, opaque, or expensive, it’s because we’re building systems that must survive 600 mph at 40,000 feet with human lives on board. The solution isn’t to “move fast and break things.” It’s to align executive vision with engineering reality, early, often, and respectfully.

Understand that structure isn’t just one team, it’s the foundation of the entire aircraft. Respect stress and design engineers. Treat FAR compliance, PDR/CDR gates, and verification milestones as lifelines, not obstacles.

That’s how you go from PowerPoint to prototype, without crashing along the way.

Exploration Systems Engineering: Project Life Cycle Module